We provide services in the field of continuous solvent extraction / vegetable oil refining and allied industries. Filtration constitutes an important part in the oil refining process. RED SEA INTERNATIONAL, with vast experience in the filtration of various slurries, has made its goal to offer the best feasible solution to any filtration problem.

We adopt a very specific approach to each customer and to each filtration problem. Here is a list of filters designed and constructed by RED SEA INTERNATIONAL:

1) Horizontal pressure leaf filter

2) Vertical pressure leaf filter

3) Polish filter

4) Cartridge filter

Continuous Neutralizing Plant

In Continuous Neutralizing Plant Our product range also comprises of Industrial Plant, Extraction Machinery.

In Continuous Neutralizing Plant Our product range also comprises of Industrial Plant, Extraction Machinery.

Continuous neutralising plants are fully automated and are capable of handling various qualities of vegetable crude oils yielding high grade finished products. various operations like pegummitig, gum conditioning, neutralising and water washing can be carried out in this plant. The plants are designed for utmost versatility, for trouble free operation and for coping up with raw materials obtained from different sources.

The raw material change-over requires very short downtime due to small volumes of oils contained in the plant and to the ease in changing the process parameters. Furthermore, the use of best centrifugal separators ensures high yields and consistently best quality of neutral oil.

The entire plant is designed for continuous operation and requires minimum attention. The equipment's can be controlled from a central control panel with large easy to read flow diagram of the process and the entire plant can be bandied by a single operator. furthermore the sturdiness and quality of all the parts employed permits simple operation and reduced maintenance.

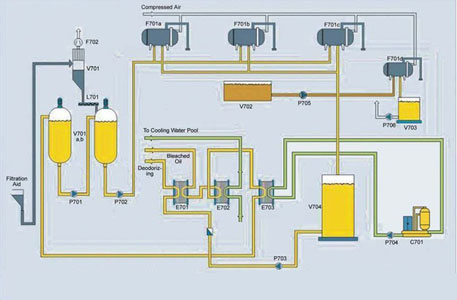

Continuous Bleaching Plant

The design of a RED SEA INTERNATIONAL continuous bleaching plant is based on the most advanced and easy to operate technology, which enables the reduction in consumption of bleaching chemicals, floor area and labour. It is also yields a final oil colour fully meeting the market standards.RED SEA INTERNATIONAL continuous bleaching plant is of versatile design and can be used for bleaching of conventional refined oils as well as pre-treated oils to be refined by the physical refining process. The bleaching operation of the oil is earned out completely out of contact with air. The slurry preparation and bleaching sre under vacuum where as the filtration is carried out in pressure leaf filters. This eliminates any possibility of oxidation of oils during the bleaching process and ensures production of high quality bleached oil.

RED SEA INTERNATIONAL continuous bleaching , incorporates, simple, yet efficient dosing system for dosing of bleaching chemicals. This system enables accurate dosing rates as per the process requirements and final colour demands. This system is based on dry dosing of bleaching chemicals and avoids completely, handling of slurry which causes operational as well as mechanical problems.

The bleaching plant is further equipped with pressure leaf filters complete with stainless steel woven wire mesh filter leaves. The filters are further provided with pneumatically operated butterfly valves. The incorporation of pressure leaf filters ensures lower oil losses in the spent earth. The plant is provided with comprehensive instrumentation and control system for efficient control of all significant process parameter ensuring high quality oil consistently.

Dewaxing Plant

RED SEA INTERNATIONAL dewaximg plamts are specially designed to suit the present market requirements of quality refined oils.

RED SEA INTERNATIONAL dewaximg plamts are specially designed to suit the present market requirements of quality refined oils.

The dewaxing flants are incorporated with intrinsically designed crystallizes and maturators, which are specially made for very slow cooling with continuous agitation for better heat transfer.

In the process the oil to be dewaxed is passed through heat exchanger wherein the temperature of oil is brought down to ambient temperature and fed into the crystallizes for nuoleation and crystal formation under low temperature. The maturators are utilized for propagation and crystal growth of waxes and finally the crystallized mass is filtered in plate and frame type filter presses. The dewaxed oil such obtain ensures clarity of oil even at lower temperatures.